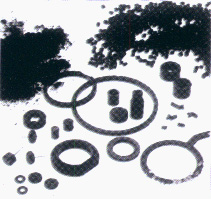

Bonded Ferrite Powder

Specifications of YX Plastic Bonded Ferrite Magnetic Materials

YXC series Strontium plastic bonded Ferrite Magnetic powders are suitable for making various bonded magnets.They have good compatibility with different kinds of composite size,such powders have high filling capacity.They can be used for making different kinds of magnets by extrusion or injection molding,The strict quality control system of our plant ensures that the quality is stable and consistent.

1. Material Properties

|

Type

|

Material

|

Qualified standard of magnetic property

|

Average granularity

(um)

|

Water content of fine powder (%) |

Forming method

|

||||

| Br (mT) | bHc (KA/m) | iHc (KA/m) | (BH)max (KJ/m3) |

Test Method

|

|||||

| YXF-1 | BaFe12O19 | 135 | - | 183 | - | Green piece | 2-4 | <=0.5 |

Extrusion |

| 150 | 95 | 167 | 3.58 | calendering | |||||

| YXF-2 | BaFe12O19 | 140 | - | 183 | - | Green piece | 1.1-1.4 | <=0.5 | |

| 180 | 115 | 167 | 5.57 | calendering | |||||

| YXF-2b | BaFe12O19 | 145 | - | 160 | - | Green piece | 1.5-1.8 | <=0.5 | |

| 180 | 107 | 143 | 5.17 | calendering | |||||

| YXF-2c | SrFe12O19 | 145 | - | 160 | - | calendering | 1.8-2.1 | <=0.5 | |

| 180 | 107 | 143 | 5.17 | calendering | |||||

| YXF-2S | SrFe12O19 | 145 | - | 183 | - | Green piece | 1.1-1.4 | <=0.5 | |

| 180 | 115 | 167 | 5.57 | calendering | |||||

| YXM-2Sb | SrFe12O19 | 145 | - | 160 | - | Green piece | 1.5-1.8 | <=0.5 | |

| 180 | 107 | 143 | 5.17 | calendering | |||||

|

YXM-2Sc |

SrFe12O19 | 145 | - | 160 | - | Green piece | 1.8-2.1 | <=0.5 | |

| 180 | 107 | 143 | 5.17 | calendering | |||||

|

YXF-3 |

SrFe12O19 | 140 | - | 215 | - | Green piece | 1.3-1.6 | <=0.5 | |

| 240 | 160 | 207 | 10.34 | calendering | Magnetic orientation | ||||

| YXF-4 | SrFe12O19 | 140 | - | 263 | - | Green piece | 1.3-1.6 | <=0.5 | |

| 240 | 160 | 207 | 10.34 | calendering | |||||

| YXF-4b | SrFe12O19 | 140 | - | 280 | - | Green piece | 1.0-1.3 | <=0.5 | Calendering orientation |

| 240 | 167 | 239 | 11.1 | calendering | |||||

2. Procedure Summaries

- Before production,the powders should avoid being humidified,and avoid being mixed with other material and impurity.

- The mixture retio of binders and plasticizers should be defined according to the grade of the powder.The powder and binders and plasticizers should be mixed uniformly.

- The working temperature of extruding should be controlled between 50OC to 90OC.(calendaring plate is usually between 80OC to 120OC)

- Please adjust the extruding speed,calendaring speed and times,according to the property required.

Copy Right © 2004-2006 YUXIANG Magnetic Materials Ind. Co., Ltd. All Rights Reserved

Copy Right © 2004-2006 YUXIANG Magnetic Materials Ind. Co., Ltd. All Rights Reserved